News

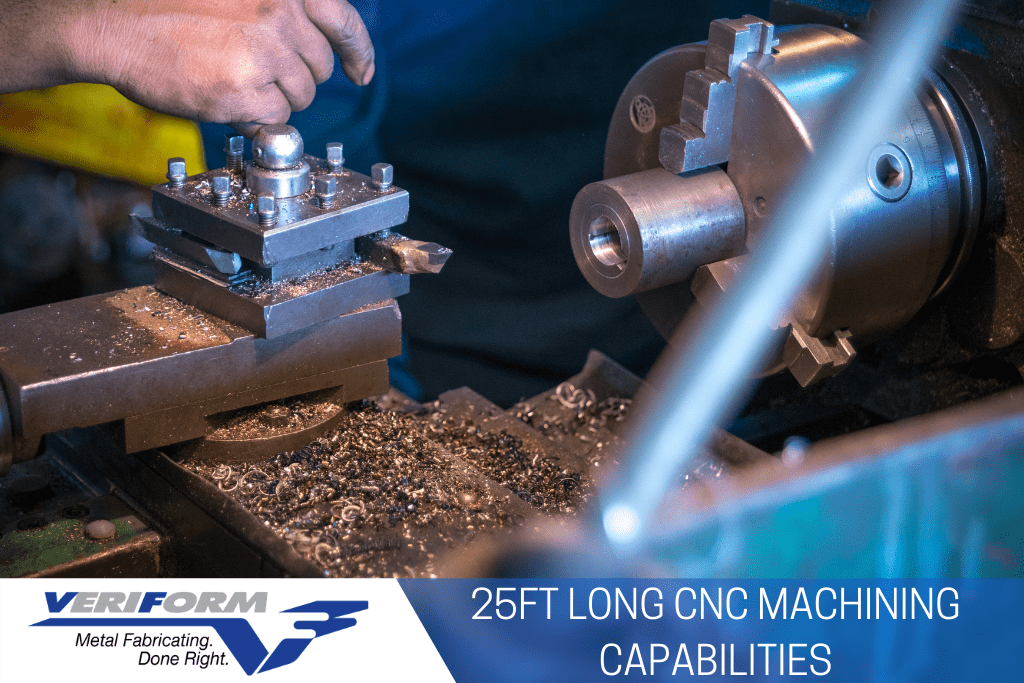

25ft Long CNC Machining Capabilities

Long gone are the days of traditional machining. Computer Numerical Control (CNC) is a process where an operator implements metal manufacturing instructions using a computer console. During the past 24 years, VeriForm has remained dedicated to our customers. We’ve made an everlasting commitment to our core values: community, sustainability, and education. In our continued efforts to be leaders in precision sheet metal fabrication services, we are excited to announce our new Canadian 25ft long CNC Machining Centre, an upgrade from our previous 20ft long.

Benefits Of A 25ft Long Machining Center

Finally, the longer CNC Machining Centre is capable of milling and drilling your larger parts with less repositioning. This successfully grants more efficiency and better productivity for our valued clients. Our new drilling machine now offers drilling, milling, tapping and other processes on larger parts, which the smaller 20ft long machine could not handle. The 25ft long machine center can now machine an XY Axis up to 2ft x 25ft. After decades of experience, we understand that there is more to be done and productivity is second to none. Discover if CNC Machining is right for you.

CNC Machining Operations Available At VeriForm

Our Machining Centre at VeriForm is long enough to have multiple workstations duplicated, which ensures high uptime and productivity. The following machining operations are available:

- CNC Plasma Cutting: Create 2D shapes and figures from sheet metal with high temperature and high-velocity streams of ionized gas.

- Tapping: Internal threads (up to M40 Thread) are created in the product so that fasteners can be used to connect parts easily.

- CNC Boring: Drills circular internal profiles in a hollow piece or on a hole.

- Milling: Progressively removes small chips using a rotating cutter tool.

- Slotting: Cutting common shapes into a straight slot (rectangular or square), or a keyway, locking slot that is curved on the end.

- Drilling: Drills holes into metal pieces, up to 1.5” diameter.

- Beveling: There are many critical issues to address when beveling. From the degree of the angle to the length of the bevel, it requires various levels of cutting tools, years of experience and skill sets. It’s the process used to prepare metal for a welded seam. At VeriForm, prepared parts can be welded by adding a bevel on weld joint parts. Our bevellers include a Pullmax X97, Heck 9000 or Trumpf handheld unit.

- CNC Countersinking: Allows screw heads to “sink” into the metal rather than protrude from the outer surface.

VeriForm Will Continue To Improve

In the meantime, continuous improvement is never-ending and our 25ft long CNC Machine Centre is a step in the right direction. As technology continues to advance, so will VeriForm. Without delay, VeriForm offers personalized services within 24 hours of initial contact. Our goals to become greener, and 98% or better for on-time delivery is some of our next step towards that improvement. VeriForm has committed to your success for at least 24 years now and they will continue to meet our client’s expectations when it comes to quality metal fabrication. Experience a cut above the rest and contact VeriForm today for more information.