Metal Rolling

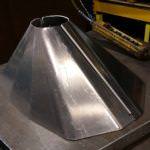

VeriForm has over 20 years of experience in metal rolling and rolled metal products. VeriForm’s Italian metal rolling machine delivers precise sheet metal and structural rolling. A team of highly trained professionals operates the machines to ensure that the results are perfect to specifications. Explore the following VeriForm Rolling Types:

Metal Rolling is a metal forming process, comparable to the rolling of dough, where metal stock is passed through rolls to uniformly reduce its thickness.

What is Camber in Metal Rolling?

Throughout the rolling process, metals are subject to tremendous operating conditions that can impact the metal’s rigidity and strength. As such, preventative measures like rolling with camber (an extra thickness), amongst others, are implemented. Rolls are ground so the metal is thicker in the center as a way to offset possible deflection.

Have a Question for Us? Ask Our Experts and Get The Engineering Support You Need!

Benefits of VeriForm Metal Rolling

- Quicker Fabrication Times

- Very High Strength

- Cost-Effective Solutions

- 10 Foot-Wide Rolling Capabilities

Learn More About the Capabilities of Our Team

We are the industry’s leaders in complex rolling projects. With our years of experience, in-house experts, and high precision equipment, you can be confident that your project will be on spec, regardless of size.