Welding - CWB CSA W47.1 & W47.2 Division 2 and CSA W59

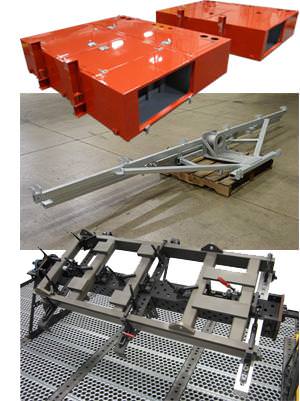

At VeriForm, our greatest strength is our dedication to personalized service and the attention to welding detail. Meeting your deadlines with our high-quality product is simply standard practice.

We proudly employ only CWB CSA W59-24 W47.1, 47.2 qualified welders, and retain a CWB Certified and Qualified Welding Engineer, to ensure your specifications are met on every project. Your work will also be supervised by our on-staff CWB Certified Welding Supervisors.

All CWB certified welding of large, long, or complex parts is performed on our state-of-the-art German-made Demmeler Bluco fabrication tables. Bluco is one of North America’s leading producers of ultra-precision welding tables. It is our belief that in order to complete superior quality certified welding, we need to use the very best equipment.

- Our experts can MIG or TIG weld any shape, even those that can be slipped over a mandrel.

- We employ an in-house certified welding inspector to ensure quality throughout the entire process.

- Processes available: SMAW, GTAW, GMAW, FCAW, MCAW, LBW and CW Laser.

- Multiple Stations: Bluco Demmeler and Weldsale tables up to 15 x 30 feet.

- Meta-Lax Stress Relieving System.

- Vibratory stress relieving of weldments up to 40,000 pounds.

- Ideal for relieving thermally induced stresses.

- Data graph printout documents the results of each part – unit is portable.

- When we weld stainless, VeriForm has the equipment to passivate (ie. clean and return to original corrosion-resistant state) the stainless steel. This removes discolouration and brings the stainless state back up to its virgin state. To perform the passivation, VeriForm uses a Surfox 304 machine to restore the stainless per ASTM A967 and A380 methodology. VeriForm can provide its certification for the work performed.

It’s a combination of our state-of-the-art equipment, skilled craftsmen, and proven techniques that ensure consistency and customer satisfaction every time. Call VeriForm today for an estimate.