News

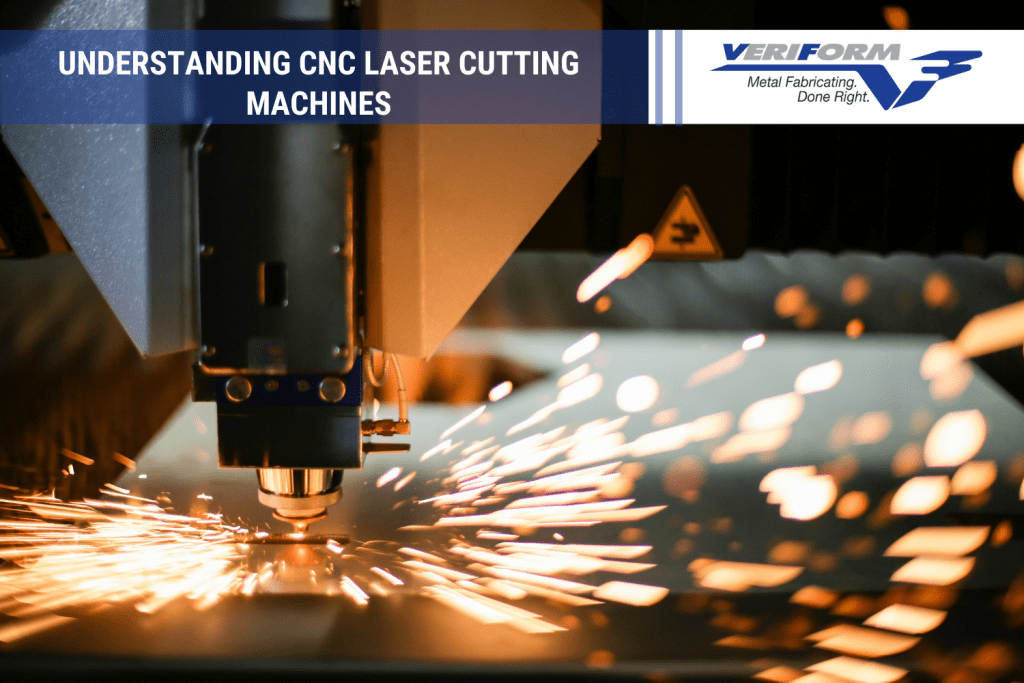

Understanding CNC Laser Cutting Machines

Laser cutting technology, as the name suggests, uses a powerful laser to efficiently cut materials. It’s a fabrication process that utilizes a high-powered laser beam to cut materials with great speed and accuracy. While traditionally used for industrial manufacturing applications, laser cutting is now increasingly used by small businesses and hobbyists. Laser cutters can be used to cut a range of materials: metal, plastic, wood. Glass, gemstone, and paper. It can produce intricate and complex parts without the need for tailored tooling.

Lasers are used for a broad range of applications – cutting metal plates is just one of them. Laser cutting machines produce incredible results when it comes to cutting steel, stainless steel, and aluminum plates. For example, the process yields a small kerf width, excellent cut quality, and a small heat-affected zone. Besides, you can cut very intricate shapes and holes.

CNC Laser Cutting Machine

A CNC machine is a programmable device that is capable of autonomously performing various tasks. A CNC laser cutting machine is controlled through written code which determines everything from RPMs to the movement of the cutting head. All CNC machines are run by computers. The function of a CNC machine is to take human input and translate it into movements through code. CNC laser cutting machines outperform every other cutting tool when it comes to the repeatability and precision of the manufacturing processes.

Laser cutting is one of the most widely used manufacturing processes that have applications in automotive, aerospace, semiconductor, electronics, and medical fields. The cutting technique works in many different ways as compared to how old cutting technologies work, opening up new possibilities for quality and reliability.

The CNC Programs Command the Following Actions in a Machine Based on Human Input:

- How fast to move the cutter

- How fast to turn the spindle

- The direction in which the cutter moves

- Which cutter to use

- When to turn on or off the coolant and so on

Types of Laser Cutting

Fabricators use a variety of laser cutting machines that can be categorized as liquid, gas, and solid-state lasers. Cutting techniques are differentiated based on the active laser medium. The two major types of laser cutters use solid-state lasers and CO2. A CO2 laser is ideal for cutting non-metal materials as the early models were not powerful enough to cut metals. However, the latest CO2 lasers are now capable of cutting metals. Most fabricators use these machines to cut non-metal and organic materials such as leather, wood, and rubber.

VeriForm Offers Top-Notch CNC Machining Services

Superior dimensional accuracy and a variety of cutting capabilities make CNC laser cutters ideal for end-users. Controlled by software, CNC laser cutting delivers stunningly accurate cuts, making it a must-have tool for progressive fabrication shops.

At VeriForm, our metal fabrication experts use CNC laser cutting tools to create unique parts and exceed customer expectations in terms of quality, speed, and affordability. From countersinking and drilling to cutting and tapping, we employ CNC machines to meet the emerging needs of our customers.

As a leading metal fabrication company in Canada, we have been using CNC laser cutting machines for over 20 years to provide high-accuracy cuts of some of the largest pieces of metal in North America. With CNC Laser Cutting, we cut up to ¾in x 80in x 160in with the accuracy of +/- 0.005in.

Applications of a CNC Laser Cutting Machine

If accuracy, precision, and high-quality edge finishes are prime concerns of a project, it becomes indispensable to use CNC cutting machines. There are several types of laser cutting: fusion cutting, scribing, and oxidation. With less physical damage, waste, and material contamination than other cutting techniques, CNC laser cutting is an ideal choice for many metal fabrication processes. However, this might not be a suitable approach when it comes to materials that require secondary finishing and machining work.

Conclusion

It’s time to take advantage of VeriForm’s CNC machining capabilities! If you need to get your CNC cutting done in a short time and with impeccable accuracy, VeriForm is ready to exceed your expectations. As an Ontario-based fabrication shop, we use fully automated cutting and quality assurance systems to accommodate even the most demanding projects.

Ready to get premium quality CNC laser cutting services in Ontario? Get a free quote right now!