News

NEW EQUIPMENT ALERT!!!

NEW EQUIPMENT = NEW CAPABILITIES

At VeriForm we are always searching for Innovative Fabricating Equipment to supplement our current capabilities. We have recently added two new pieces of equipment that expand our service offerings in new and exciting directions.

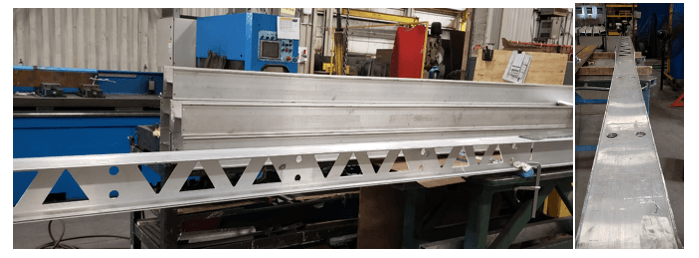

25 FOOT LONG VERTICAL MACHINING CENTRE

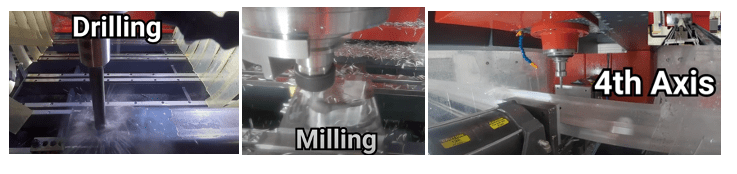

Introducing our new 25ft CNC Machining Centre, capable of high-speed drilling and milling of your large and long parts in one setup with less repositioning. Our new Machine Centre can now machine an XY AXIS up to 2ft x 25ft.

A 5-axis machine equipped with a high speed spindle motor, which can mill, drill, tap and saw tubes, profiles and extrusions in aluminium, steel and composites. With our new 25ft CNC drilling machine we can now offer drilling, milling, tapping and performing other processes on large parts that our smaller 20ft machine did not have the capacity to handle.

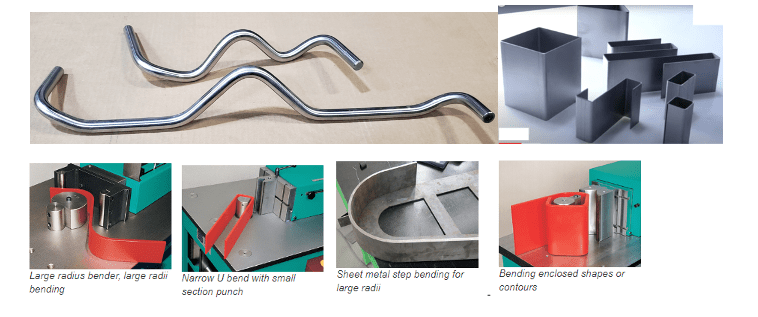

HORIZONTAL HYDRAULIC PRESSBRAKE

Everyone is familiar with the traditional VERTICAL Pressbrakes (we have five!) but have you ever heard of a HORIZONTAL Pressbrake? Recently purchased from Spain, our new Horizontal Pressbrake allows us to bend parts that a Vertical Pressbrake cannot bend due to part collisions with the ram/bed of the pressbrake.

Our Horizontal Pressbrake now allows us to bend pipe, roundbar, flatbar, channel or other HSS in configurations that would be impossible on our conventional pressbrakes. Ideal for bending roundbar and flatbar, this machine is made for producing clamps, bending rods and completely closed-fold fabrications.

Example applications include and are not limited to:

- Bending and folding flat bars that allows us to fabricate completely closed pieces that would be difficult to obtain by using other machines

- Folding and bending solid rods will enable the user to manufacture all kinds hooks, chain links and also form balusters out of square or round bars, tubes for the manufacturing of parts for cold forging, railings, fences, gates, doors, railings

- Bending and curving tubes to different degrees to make tables, chairs, pool ladders, etc.

- Straightening and bending large profiles & radii with complicated curves and bends plus the ability to straighten faulty profiles

- Cutting and shaping are other features of this versatile forming press for manufacturing flanges and clamps for fastening pipes

- Flaring tube or pipe for assembly and subsequent welding to produce exhaust pipes, water pump distributors, metal furniture, railings tube

- Widening and reducing the pipe ends permit joining different pipes to make berths, chairs, irrigation systems, tents, greenhouses etc

We can have custom tooling made for your application within a 2 to 3 days. If you have an impossible part to bend, send us a request for quote and we can give you a quick assessment on whether we can bend it for you on our NEW HORIZONTAL PRESSBRAKE!

Call us today for more information on a quote for your machining requirements 519-653-6000