Laser Welding & Laser Spot Welding Services Canada

VeriForm is happy to announce the implementation of a leading-edge laser welding system on-site at our Cambridge plant late in December 2022. The American-made laser system allows VeriForm to offer customers a better weld method for stainless steel, aluminum and other unique metals like titanium, copper and brass. Contact us for our services.

Laser Welding vs TIG Welding

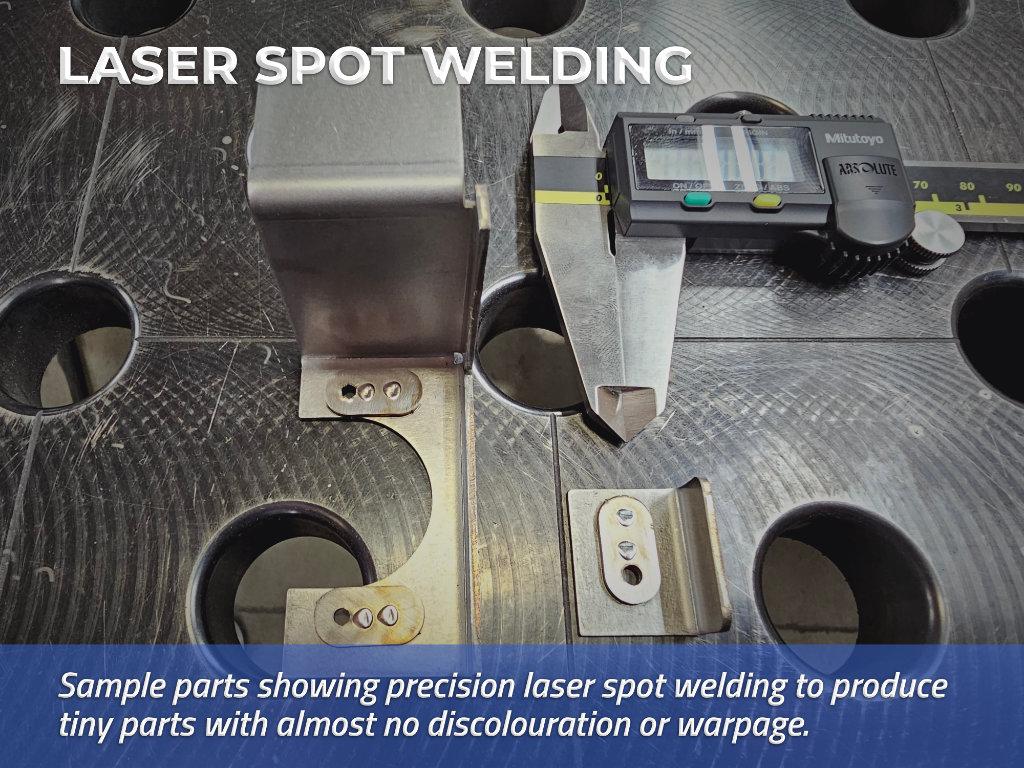

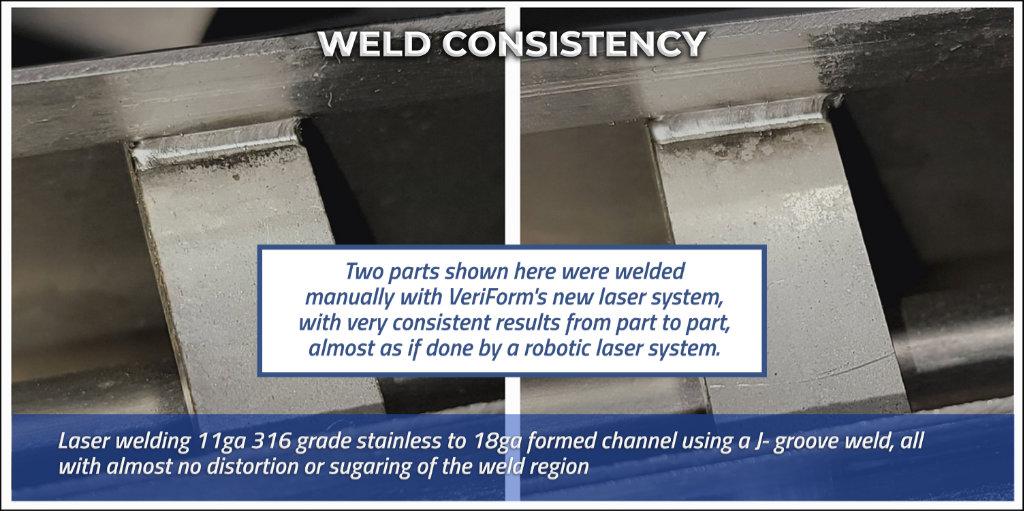

Laser and TIG welding are powerful methods to join metal parts together. However, there is a distinct difference between them, with laser welding achieving faster results, more precision control over the weld line path and superior quality perimeters compared to traditional TIG welding operations. Although more costly in terms of specialized equipment needed for operation, it can benefit projects that use thinner materials as heat build-up could result in distortion if other techniques were applied. On the other hand, although requiring more significant knowledge from operators, TIG provides an economical option for larger components or those needing thicker sections joined up.

Laser Welding vs MIG Welding

Laser welding offers unparalleled precision and speed for industrial and commercial welding operations. This makes it an ideal choice for jobs that need to be done quickly without sacrificing accuracy.

VeriForm Laser Welding Experts

Whether you need welding for aerospace, automotive, medical or any other industry, VeriForm has the expertise and experience to meet your needs. Don’t settle for mediocre welding services that can compromise the quality of your products. Contact us today to learn more about how we can help you achieve your welding needs

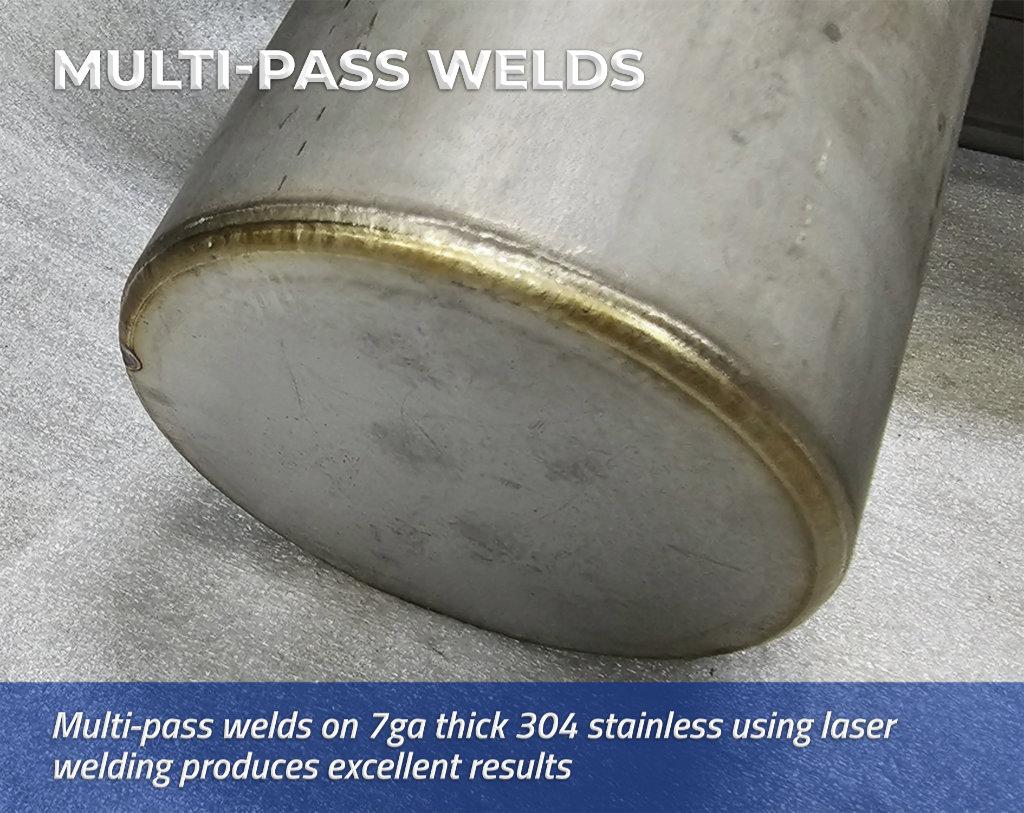

Laser welding at VeriForm replaces TIG welding and eliminates 90% of distortion, equating to far better results!