News

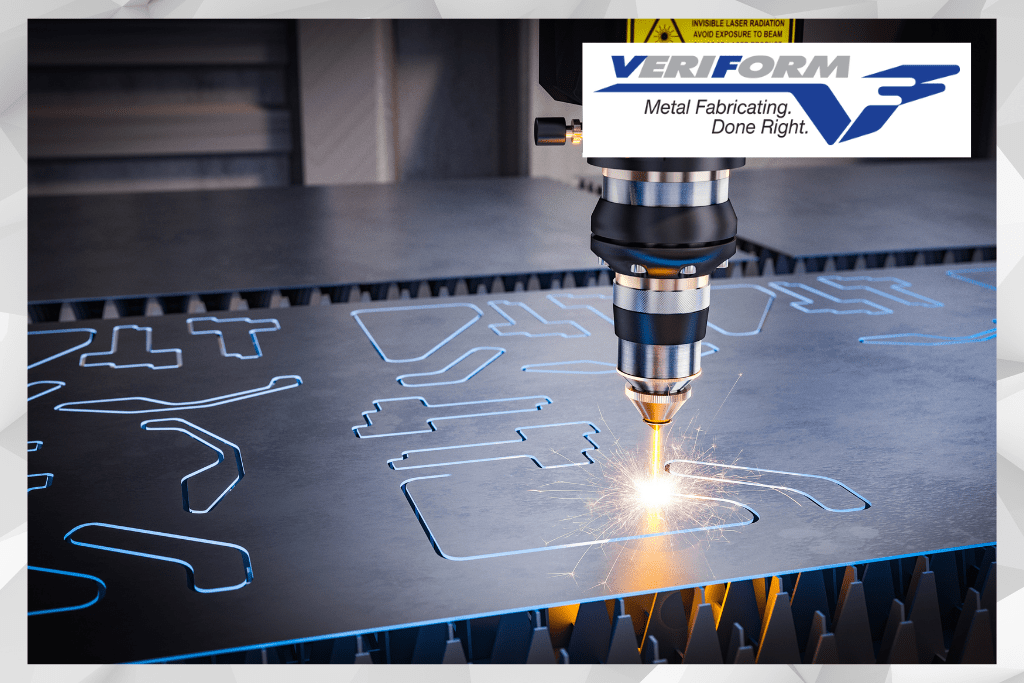

How Does a Laser Welding Machine Work?

A Deep Dive with Veriform’s Metal Fabrication Experts

In the rapidly evolving landscape of metal fabrication and welding, laser welding technology stands out for its precision, efficiency, and versatility. As industries from aerospace to automotive increasingly rely on this advanced technique, understanding the workings of a laser welding machine becomes essential. Veriform, a company at the forefront of metal fabrication and specialized welding services, provides an expert overview of how laser welding machines operate and their significance in modern manufacturing.

The Fundamentals of Laser Welding

Laser welding employs a concentrated beam of light to fuse materials together. This process is distinguished by its ability to focus a high amount of energy into a small, precise area, allowing for deep penetration welds with minimal heat spread. Here’s a step-by-step look at how a laser welding machine operates:

1. Generating the Laser Beam

The core of a laser welding machine is its laser source, which generates a beam through the stimulation of a lasing medium by electrical discharges or lamps. The most commonly used lasers in welding are fiber lasers and CO2 lasers, each suitable for different materials and applications.

2. Beam Delivery and Focusing

Once generated, the laser beam is directed toward the workpiece using a series of mirrors or a fiber optic cable. Arriving at the welding head, the beam is then focused to a precise point using lenses or a curved mirror. This focused beam is what makes laser welding so effective for detailed and high-strength welds.

3. Material Fusion

When the focused laser beam hits the material, its intense energy heats and melts the material in a localized area, allowing two or more parts to be fused together. The depth and strength of the weld are controlled by the laser’s power, the duration of exposure, and the speed at which the beam moves across the material.

4. Cooling and Solidification

After the laser passes, the molten material cools and solidifies quickly, forming a strong, precise weld. This rapid cooling also helps minimize the heat-affected zone (HAZ), preserving the properties of the material around the weld.

Advantages of Laser Welding

Veriform’s adoption of laser welding technology is driven by its numerous benefits, including:

- Precision: The ability to focus the laser beam on a very small area allows for intricate welds on delicate components.

- Speed: Laser welding is faster than traditional welding methods, enhancing production efficiency.

- Versatility: Capable of welding a variety of materials, including metals that are difficult to weld by conventional means.

- Quality: Produces high-quality welds with low distortion and a clean appearance, reducing the need for post-weld finishing.

Applications in Metal Fabrication

Laser welding’s precision and versatility make it ideal for a wide range of applications, such as:

- Automotive Manufacturing: For welding components with precision and strength, contributing to lighter and safer vehicles.

- Aerospace Industry: In the fabrication of aircraft parts, where the integrity of each weld is critical.

- Medical Devices: For assembling small, complex devices where traditional welding methods are impractical.

Veriform’s Expertise in Laser Welding

At Veriform, our extensive experience in metal fabrication and welding positions us as a leader in utilizing laser welding technology. Our state-of-the-art laser welding machines, combined with our skilled technicians, allow us to offer unmatched precision and quality in our welding services. We’re committed to pushing the boundaries of what’s possible in metal fabrication, leveraging the latest technologies to meet our clients’ needs.

Conclusion

Understanding how a laser welding machine works illuminates the possibilities and advantages it brings to metal fabrication and welding. With its precision, speed, and versatility, laser welding is transforming manufacturing processes across industries. Veriform remains at the cutting edge of this transformation, offering expert laser welding services that meet the highest standards of quality and efficiency.

For those looking to harness the power of laser welding in their projects, partnering with Veriform means choosing a leader in metal fabrication and welding innovation. Visit us to explore how our laser welding capabilities can enhance your manufacturing processes and products.