News

Your Basic Guide To Galvanized Steel

It has been around for more than 150 years and is used for a wide range of applications. This includes construction, residential use, rail, road, agriculture, etc. Galvanized steel is steel that has been coated in a protective layer of zinc. There are many benefits to using this material that we will discuss further. The fact is that it’s a tough and versatile metal. Most importantly, it’s corrosion-resistant. To learn more about galvanized steel, keep reading.

Galvanized Steel – What Is It?

We know that steel itself is a strong durable metal, but galvanized steel can be even better. The zinc galvanized steel is coated in prevents corrosion. Normal steel, despite being strong and tough is susceptible to rust and corrosion. This can be caused by rain or constant contact with other liquids as well as humidity in the air. Corrosion is the main enemy of steel, and the process of galvanizing prevents the onset of this issue.

Why Is Zinc Used?

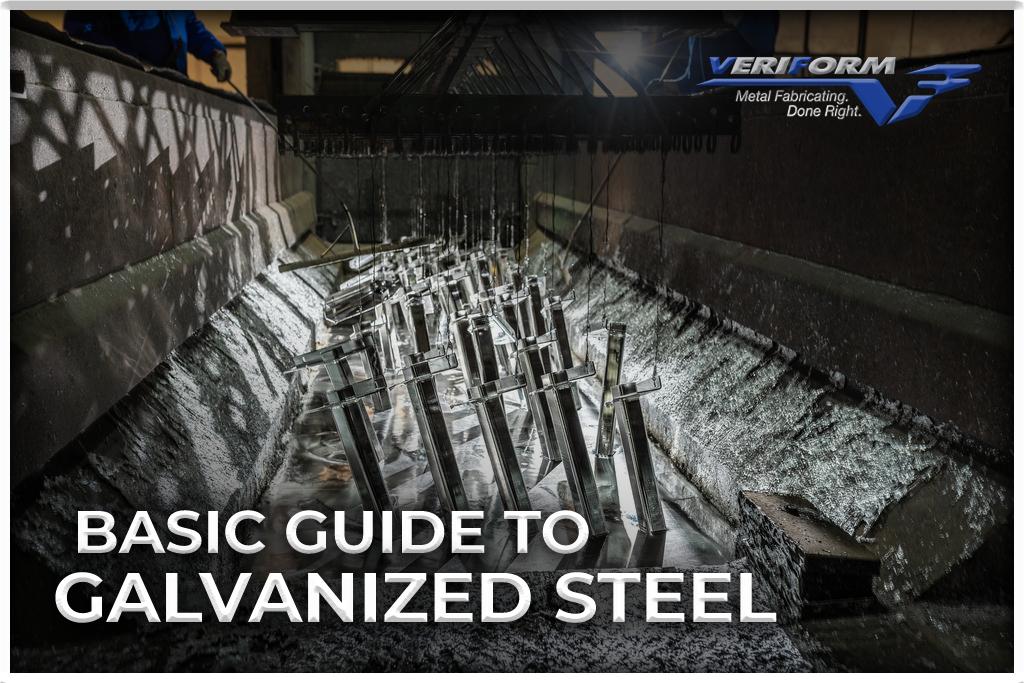

While other metals can also help in this regard, zinc is affordable, easy to apply, and extremely effective. The addition of zinc, in the process of galvanization, improves the steel and minimizes the risk of corrosion. The process was established in England and France as far back as 1837. At that time, the steel was dipped into molten zinc and the process was known as hot-dip galvanization, a process still used to this day.

The Process of Galvanizing Steel

There are various ways to galvanize steel. When molten zinc is added to steel, a chemical reaction causes it to adhere to the steel providing the protective coat. Hot dipping is the most common way to do this but there are other methods. These include zinc, electroplating, mechanical plating, and sherardizing. Zinc metal spray and continuous strip galvanizing are additional methods. The ideal method will depend on the application and the applicator, hence why it’s important to work with companies you can rely on.

The Benefits of Galvanized Steel

The main benefits of galvanized steel are that it is tough, durable, and corrosion-resistant. This makes it a relatively sustainable material to use in structures. Despite the higher initial costs, the strength and durability make it an economical choice over time. Little to no maintenance will be needed for many decades. The galvanizing process is effective and delivers complete coverage. The bond that is formed when zinc is added is extremely strong and reliable. It has proved itself over time, making it predictable. You can measure the lifespan according to the coating thickness with a high rate of accuracy. It also helps during transport, handling, and storage. It makes the project easier to complete and ensures the integrity of the result with minimal hassle and fuss.

What Industries Use Galvanized Steel?

It is used extensively in various industries wherever strong corrosion-resistant metal is needed. This includes:

- Construction

- Automotive

- Telecommunication

- Agriculture

- Solar

Conclusion — A Metal Fabrication Company You Can Trust

For all your metal fabrication needs, speak to the trusted team at VeriForm. They have more than 24 years of experience in the business and have developed a solid reputation. CNC machining and CNC bending are just some of the services they have to offer. Many capabilities are available including metal bending parts up to 21ft wide, precision plasma cutting, and wide format metal rolling. So, when you’re looking for metal fabrication that needs to be done right, give VeriForm a call or fill out their online contact form to get your free quote.