News

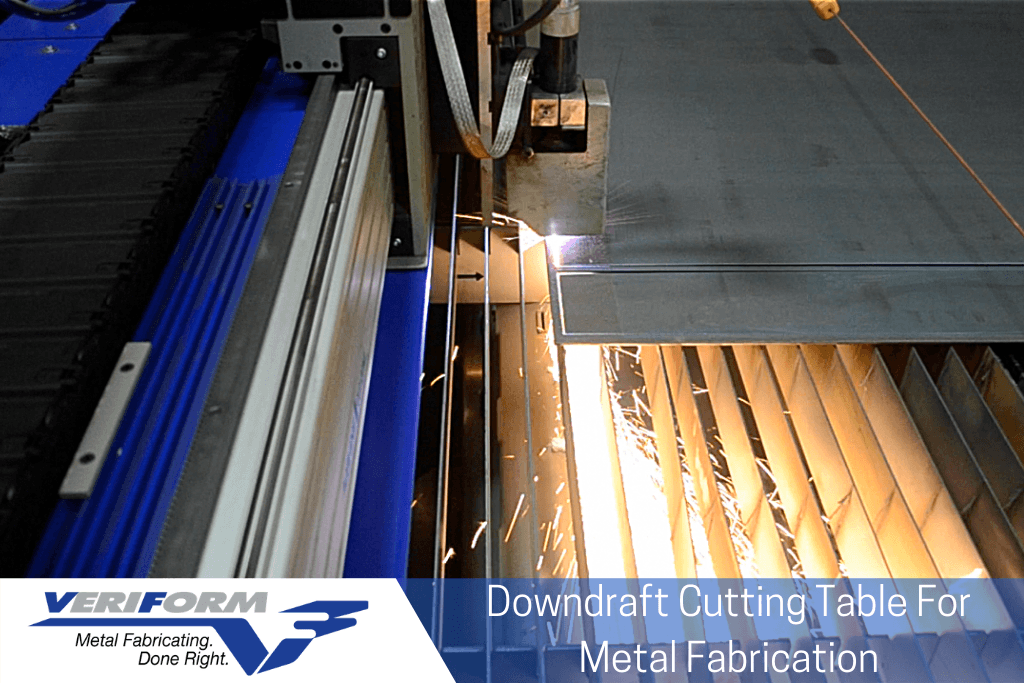

Downdraft Cutting Table For Metal Fabrication

During certain processes such as metal fabrication and woodworking, it is essential to control the dust and fumes surrounding the work environment. One highly recommended solution is a downdraft table, where air flows down through the table and pulls dust and fumes away from your operating area. Get more uptime from VeriForm’s mechanical design, and superior smoke and dust removal by purchasing a downdraft cutting table. These systems are built for long, dependable service with lower operating costs and downtime.

How Does A Downdraft Cutting Table Work?

The concept of a downdraft cutting table is to pull air from the plasma plate, below the table so that none of the plasma smoke will escape. This allows materials to be cut more efficiently and draws all the toxic fumes and dust away from the operator. See how it works. Improved ducting underneath the cutting table cuts dust collection costs by 70-80%. Not only do you get to breathe easier, but you also save money from the increased uptime.

The tables can be custom-built, depending on the client’s needs. They’re customizable and multipurpose ranging in various sizes. Not only do the workers get to breathe easier, but money can be saved from the increased uptime. They can localize smoke removal right at the source for better dust and pollutant extraction throughout the table. Not only does it improve the health of your employees, but the service life of the components and electronics will also be longer as well. Higher dust recovery rates mean more productivity and less time spent cleaning.

Why Should You Have One?

If you are not using a downdraft table, you will most likely be using a water table. Water tables tend to be messier and involve more cleaning. Using a water table can make cutting speeds slower and less productive especially if water gets in the way during a cut. The further downsides to water tables can be the fact that they are more difficult to clean and maintain. Water exposed to colder temperatures can freeze, and it requires regular treatments to avoid potential health hazards. There is also the risk of explosion when plasma, aluminum, and water react together.

Besides making water tables obsolete, downdraft tables can lower certain health risks such as lung and throat cancer, asthma, bronchitis, and other serious diseases. These are all valid reasons as to why you should consider purchasing a downdraft cutting table for your workplace.

A Long-Term Investment Worth Investing

Upfront costs may be higher, but with the added productivity from purchasing your very own downdraft cutting table, you can experience savings in annual costs and return on investments. Let your employees work better by equipping them with the proper work environment and equipment. To learn more about the benefits of downdraft systems and other metal fabrication inquiries, contact VeriForm today. Experience our commitment to our customers first-hand.