News

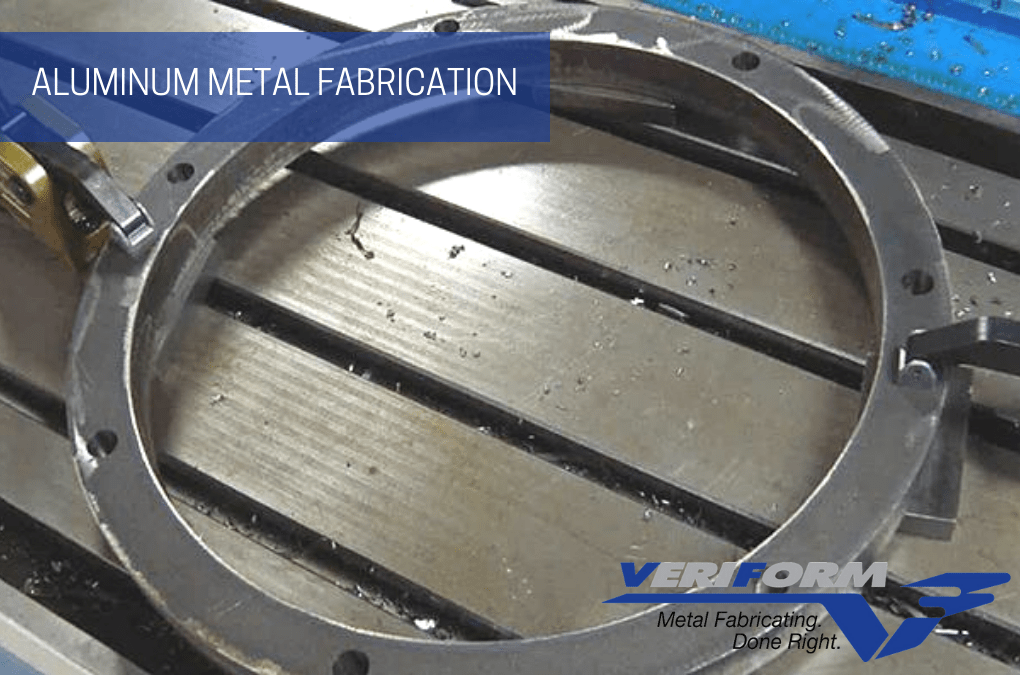

Aluminum Metal Fabrication

Aluminum is one of the most durable metals, and its robustness makes it suitable for various uses. The aluminum metal fabrication process can mold this metal into any desired product such as solar panels, tools, or any other desired shape. Aluminum products are used in various industries, including housing, energy, electronic enclosures, medical, aerospace, defence, and many more. Projects including CAD/CAM and Solidworks, custom tooling designing, prototyping, Design/DMEA, and formed parts flattening can be done through the process of fabrication.

Even though there are numerous benefits of using aluminum fabrication, the process in itself is complicated. Aluminum metal is softer than steel, and hence its handling needs to be done only by professional companies such as VeriForm. This article will cover a majority of everything there is to know about aluminum metal fabrication and the kind of projects that can be done through this process.

What Is Aluminum Metal Fabrication?

Aluminum metal has a unique set of properties that make it one of the most popular materials for fabrication. It is lightweight, has an excellent strength-to-weight ratio, is soft and easy to shape, resistant to corrosion, and is nontoxic. The fabrication of aluminum can be done through various techniques. These techniques include extrusion, drawing, forming, casting, forging, welding, adhesive bonding, machining, drilling, CNC laser cutting, and CNC plasma cutting.

Types of Aluminum Metal Fabrication Services

Numerous services come under aluminum metal fabrication. These services aid in designing products and parts with metal. The entire fabrication process includes designing the component and manufacturing it. Explained below are some of these fabrication services:

- CAD/CAM and Solidworks: Computer-aided design and manufacturing are two very advanced yet useful aluminum fabrication services that any good company will provide. The CAD is used to design the parts with various software, and CAM used these designs to manufacture the parts for model generation. At VeriForm, the process is done with the help of Solidworks software. Solidworks is one of the best CAD and CAM software that offers 2D and 3D model designing features for engineers.

- Custom Tooling Designing: Tooling is the procedure used to design and engineer specific tools required to manufacture individual components. VeriForm offers custom tooling designing, which means that the tools are customized depending on the product’s as well as the companies’ needs and manufacturing.

- Design/FMEA and Prototyping: FMEA or Failure Mode and Effects Analysis is a method of analyzing any potential defects and failures in the product’s design. Another process that is a part of aluminum metal fabrication is prototyping. It means creating a small prototype of the aluminum part and checking its usability before manufacturing the entire product.

- Formed Parts Flattening: The process of taking something with a round shape or raised shape and pressing it down to form flattened parts is called flattening.

- CNC Plasma and Laser Cutting: Plasma cutting is a process in which an accelerated jet of hot plasma is used to cut aluminum, and laser cutting is the process that uses laser beams to make these cuts. The plasma cutting at VeriForm can be done on stainless steel and aluminum from 18ga to 1.5” thick x 18.0 ft. x 40 ft. table. The laser cutting can be done up to ¾” x 80” x 160” (4000W) +/- 0.005” Accuracy.

- Shearing: The process of cutting straight lines on a flat metal is called shearing. At VeriForm, the CNC shearing process is used up to ½” x144” with a 48” CNC back gauge.

- CNC Punching: Computer numerically controlled punching is a process in which different sized holes are punched on an aluminum sheet pre-designed and controlled through computer software. The punching can be done on aluminum sheets of up to 1.5” diameter in 1” metal.

- CNC Bending Forming: The process of reshaping the metal sheet from flat to bent through a press and computer numeric control is called bending forming. The press at VeriForm can do complex kinds of bending of metal to any shape. They have machines that are capable of bending 56-tonne x 48” parts to 900-tonne 7-Axis CNC X 240” to ¾” x 20 fee bending parts.

- Welding: Joining two or more sheets or aluminum parts together is called welding. VeriForm has CSA 47.1 Division 2 certified MIG/TIG/Spot welding facilities. Additionally, they also offer 10 welding stations, assembly services, and painting the parts for a quality finish.

Finding the Right Professional

Aluminum, although very durable, is a metal that needs careful handling because of how malleable it can be. Welding of aluminum and laser cutting has to be done with precision because of aluminum’s high thermal conductivity. The high thermal conductivity of the metal makes fusion while welding tougher. Also, the property makes it challenging to cut thicker sheets of aluminum. Hence the laser cutting has to be done on thinner sheets. These are some points that inexperienced professionals tend to ignore.

That is why only trained, and experienced professionals will provide you with the results you need. VeriForm has over 20 years of experience in this field. They have all the latest equipment and an experienced team that can handle aluminum parts with components of up to 20 ft. They also provide services such as oversize bending and rolling along with a two-day turnaround for tooling and prototypes. Quality engineering assistance along with the above-given services is what makes VeriForm one of the leaders in the metal fabrication industry. All the more, they have CWB CSA W47.1 certified welders and skilled engineers that overlook all the activities.

Aluminum metal fabrication is one of the most useful techniques within this industry. That is why it is imperative to find the right company such as VeriForm. It knows the challenges associated with handling aluminum and has a team of experienced professionals to ensure that you get quality products. Contact us today to learn more about aluminum fabrication and how it is done along with other services.