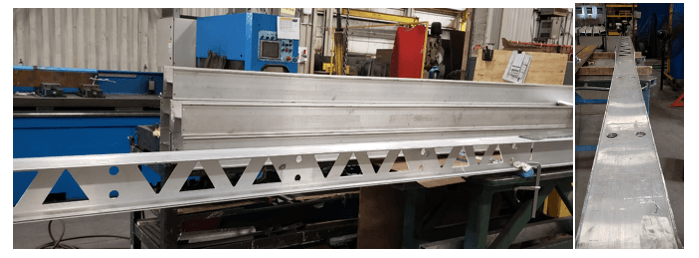

25 Feet CNC Vertical Machining Centre

Introducing our new 25 feet CNC Machining Centre!

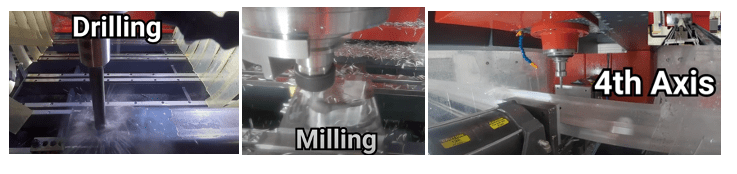

Capable of high-speed drilling and milling of your large and long parts in one setup with less repositioning. Our new Machine Centre can now machine an XY AXIS up to 2.5 feet x 25 feet. (Up to 32 inches x 300 inches long).

A 3-axis machine equipped with a high-speed spindle motor, which can mill, drill, and tap tubes, profiles and extrusions in aluminum, steel and composites. With our new 25 feet CNC drilling machine, we can now offer drilling, milling, tapping and performing other processes on large parts that our smaller 20 feet machine did not have the capacity to handle.

Call us today for more information on a quote for your machining requirements 519-653-6000

Exploring the Features and Benefits of Vertical Machining Centres

Precision and Accuracy: The Backbone of CNC Vertical Machining Centres

CNC vertical machining centres are designed to deliver exceptional precision and accuracy, ensuring that every part produced meets the strictest tolerances. With advanced software and servo motors, these machines can execute complex machining operations with unparalleled consistency, reducing errors and reworks to a minimum.

Speed and Efficiency: Streamlining Manufacturing Processes

Time is of the essence in modern manufacturing, and CNC vertical machining centres excel in delivering speedy results. These machines boast rapid spindle speeds, quick tool changes, and optimized workflows, allowing manufacturers to reduce production cycle times significantly. By eliminating unnecessary downtime and increasing productivity, businesses can fulfill orders faster and seize new opportunities for growth.

Versatility: Adapting to Varied Manufacturing Needs

One of the most remarkable aspects of CNC vertical machining centres is their versatility. These machines can handle a wide range of materials, from metals to plastics, and execute various machining operations such as milling, drilling, and tapping. The ability to adapt to different manufacturing needs makes them indispensable in industries like aerospace, automotive, and medical, where complex and intricate parts are the norm.

Automation: Simplifying Complex Operations

In today’s fast-paced manufacturing environment, automation is key to staying competitive. CNC vertical machining centres offer advanced automation features, including tool changers, pallet changers, and robotic integration. By automating repetitive tasks and minimizing human intervention, manufacturers can achieve higher efficiency, reduce labour costs, and ensure consistent quality throughout production runs.

Realizing the Power of CNC Vertical Machining Centres

Let’s dive into a couple of real-life examples to see how CNC vertical machining centres have revolutionized manufacturing processes:

Automotive Manufacturing: Enhancing Productivity and Quality

In the automotive industry, challenges often arise in balancing production efficiency with maintaining quality standards. The adoption of CNC vertical machining centres has made it possible to overcome these challenges. The precision and speed of these machines have helped reduce manufacturing cycle times substantially, leading to increased productivity and reduced time-to-market. Further, the consistency and accuracy offered by these machines have minimized defects, resulting in improved product quality.

Medical Device Manufacturing: Accelerating Innovation

In the medical device manufacturing field, it’s often difficult to match the pace of growing demand for advanced products. The implementation of CNC vertical machining centres has significantly enhanced the industry’s manufacturing capabilities. These machines, due to their precision and versatility, have made it possible to create intricate and complex medical devices with exceptional accuracy. Additionally, the increased speed and efficiency of the machining process have facilitated adherence to tight schedules, enabling the timely delivery of innovative healthcare solutions globally.

How to Choose the Right CNC Vertical Machining Centre

When considering the adoption of CNC vertical machining centres, selecting the right machine that aligns with your specific manufacturing needs is essential. Here are a few key factors to consider:

1. Precision Requirements

Evaluate the level of precision your manufacturing processes demand. Look for CNC vertical machining centres with high-resolution servo systems and advanced feedback mechanisms to ensure accurate and consistent results.

2. Production Volume and Throughput

Assess your production volume and determine the required throughput capacity. Consider the machine’s spindle speed, tool-changing capabilities, and automation features to optimize production efficiency and meet demand.

3. Material Compatibility

Consider the materials you work with regularly. Ensure that the CNC vertical machining centre you choose can effectively handle the materials and machining operations required for your specific applications.

4. Software and Programming Capabilities

Evaluate the machine’s software and programming capabilities. Look for user-friendly interfaces, compatibility with standard CAD/CAM software, and the ability to generate complex tool paths for intricate parts.

5. Support and Service

Choose a reputable manufacturer that offers reliable customer support and maintenance services. A strong support network ensures that your CNC vertical machining centre remains operational and minimizes downtime.

Embrace the Power of CNC Vertical Machining Centres

In the dynamic world of manufacturing, staying ahead of the competition requires embracing advanced technologies that enable precision, efficiency, and scalability. CNC vertical machining centres have emerged as game-changers, revolutionizing the way manufacturers operate. By leveraging their capabilities, businesses can achieve higher levels of productivity, produce superior-quality parts, and accelerate their growth.

Call us today for more information on a quote for your machining requirements 519-653-6000